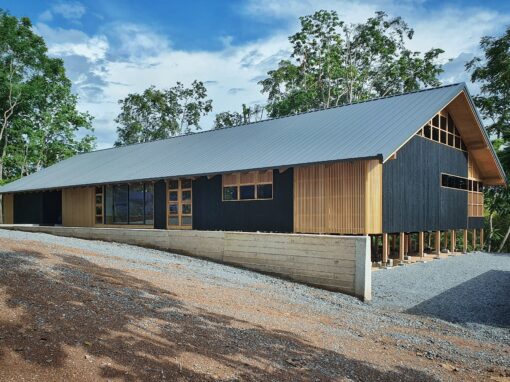

Roof House, Kinala Residence

Roof House is one of Kinala Property’s project, located in Cilandak area, Southern part of Jakarta.

Project Details

Project Owner

Kinala Property

Designer

Atelier Riri

Location

Cilandak, Jakarta, Indonesia

Project Type

Residential

Product

COLORBOND® Steel – Gull Grey

Application

Roofing

Profile

LYSAGHT® LOCKED SEAM®

Area

200 m²

As most would attest, the journey from vision to fruition is never easy. However, the builders of the Roof House achieved just that, resulting in a structure that combines form and function beautifully.

The Roof House is the work of Atelier Riri, an architecture firm renowned for creating aesthetically pleasing yet practical buildings. More than just a beautiful piece of architecture, it is built to let rainwater run off faster and distribute natural lighting across the entire space.

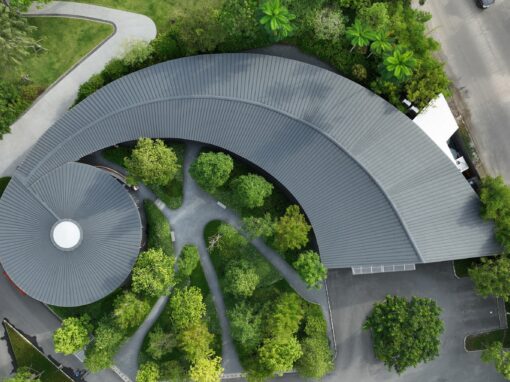

Located in the upmarket enclave of Kinala Residence, Cilandak, South Jakarta, the one-piece sloping roof and straight wall design stands out with its striking geometric form despite having many distinctive residential buildings within its vicinity.

The profile chosen was LYSAGHT® LOCKED SEAM®, the preferred choice for contemporary buildings, made with COLORBOND® steel in Gull-Grey colour.

The unique roof-to-wall connection of the structure requires a unique solution. For this, we relied on the concealed fixing of our new LYSAGHT® LOCKED SEAM® profile to achieve that continuous look. The whole process from roof production to installation took a short 2 months.

LYSAGHT® LOCKED SEAM®

LYSAGHT® LOCKED SEAM® is a profile with broad, flat pans and slender, well-defined ribs. This makes it a suitable cladding for virtually any design, especially clean and simple ones. The 32mm rib height adds a dose of contemporariness to any building cladded with it.

COLORBOND®

Tested in harsh Australian weather, COLORBOND® steel goes through extreme heat, cold, dust, rain, wind and hail. It also undergoes corrosion and durability testing. Multiple building applications were recreated to include varying pitches, profiles and product types. Even unwashed areas are part of the assessment.

During production, it’s coated with BlueScope’s proprietary metallic coating to improve corrosion resistance. After that, a thin pretreatment is applied before a primer is baked onto the surface. The final topcoat provides resistance to chipping, flaking and blistering.